THANKS TO COMPETENCE, SYNERGY, WORKFLOW OPTIMIZATION AND QUALITY MANAGEMENT, R.I.C. ENSURES THE DEVELOPMENT AND PRODUCTION OF QUALITY PRODUCTS, GUARANTEEING DELIVERY TIMES AND A CONSTANT PRODUCT QUALITY.

SERVICES WE SUPPLY

ENGINEERING & RESEARCH3D digitizing, reverse engineering, CAD, CAM, FEA, problem solving, feasibility studies, detailed engineering studies, research and consulting.

ENGINEERING & RESEARCH3D digitizing, reverse engineering, CAD, CAM, FEA, problem solving, feasibility studies, detailed engineering studies, research and consulting.

COMPRESSION MOULDINGCompression moulding is a technique which allows for a mass production of 3D components in composites combined with a constant quality. This techniques allows for the substitution of 3D forged aluminium parts lowering weight and increasing strength.

COMPRESSION MOULDINGCompression moulding is a technique which allows for a mass production of 3D components in composites combined with a constant quality. This techniques allows for the substitution of 3D forged aluminium parts lowering weight and increasing strength.

Services :

Product development, engineering, mould design, mould construction, prototyping, testing, validating, production, routing and surface finishing.

PRESS MOULDINGThis technique allows for the production of shell type composite products. Although less flexible than autoclave production, this technique consents to produce composite components in mass with a constant quality.

PRESS MOULDINGThis technique allows for the production of shell type composite products. Although less flexible than autoclave production, this technique consents to produce composite components in mass with a constant quality.

Services :

Product development, engineering, mould design, mould construction, prototyping, testing, validating, production, routing and surface finishing.

LONG FIBER INJECTION MOULDINGSince 10 years we produce high strength components with longfiber thermoplastic glass reinforced injection moulding materials. Over the last few years new materials based on carbon fiber and special polymers like PEEK, PEI, PC or nylon are available in the market allowing for the development of metal substitutes.

LONG FIBER INJECTION MOULDINGSince 10 years we produce high strength components with longfiber thermoplastic glass reinforced injection moulding materials. Over the last few years new materials based on carbon fiber and special polymers like PEEK, PEI, PC or nylon are available in the market allowing for the development of metal substitutes.

Services :

Product development, mould design, mould construction, production.

OVERINJECTION MOULDINGSometimes there is a need to combine composites with polymers in order to satisfy design or mechanical requests. In these cases over-injection moulding is an option.

OVERINJECTION MOULDINGSometimes there is a need to combine composites with polymers in order to satisfy design or mechanical requests. In these cases over-injection moulding is an option.

Services :

Product design, mould design, mould construction, production

IN-MOULD DECORATION & COATINGComposite material components often need a surface finish after beeing moulded and routed. This is normally done with the use of a coating process. Our pressmoulding technique allows for a surface layer to be co-moulded. This surface layer ensures no surface voids, a coating like top surface and the upportunity to colour this layer under the skin with multiple colours. This special layer also makes the component more tenace and can allow for overinjection. This techniques is normally identified as in-mould decoration.

IN-MOULD DECORATION & COATINGComposite material components often need a surface finish after beeing moulded and routed. This is normally done with the use of a coating process. Our pressmoulding technique allows for a surface layer to be co-moulded. This surface layer ensures no surface voids, a coating like top surface and the upportunity to colour this layer under the skin with multiple colours. This special layer also makes the component more tenace and can allow for overinjection. This techniques is normally identified as in-mould decoration.

Services :

Product design, mould design, mould construction, production.

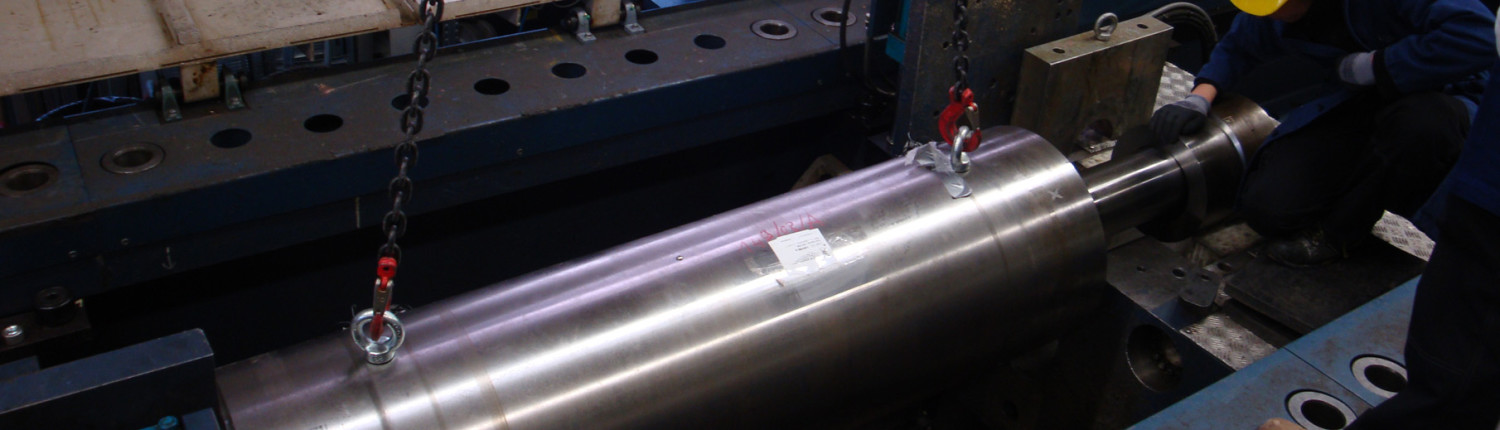

SPECIALSAt request we also develop special products for a variety of sectors in which we use technologies like M.I.M. (Metal Injection Molding), technical ceramics, gorilla glass, nano metals, anodized aluminium, INVAR, composites, PEEK or other leading edge materials.

SPECIALSAt request we also develop special products for a variety of sectors in which we use technologies like M.I.M. (Metal Injection Molding), technical ceramics, gorilla glass, nano metals, anodized aluminium, INVAR, composites, PEEK or other leading edge materials.

MEDICAL PRODUCTSWe produce and develop components for the medical and dental sector. Our main products are orthesis, dental posts, special tooling or equipment for surgery.

MEDICAL PRODUCTSWe produce and develop components for the medical and dental sector. Our main products are orthesis, dental posts, special tooling or equipment for surgery.

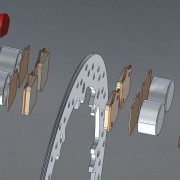

THERMOBRAKESThermobrakes is a trademark of a special heat isolating shim used in automotive brakes. This patented shim is able to reduce the brake oil temperature up to 60 degrees Celsius. This heat isolation has many advantages. It mainly reduces vapor lock and aging of the seals. tests have also shown better brake efficiency in both very hot as very cold conditions. This product is actually distributed by EVO Corse ( www.evocorse.com )

THERMOBRAKESThermobrakes is a trademark of a special heat isolating shim used in automotive brakes. This patented shim is able to reduce the brake oil temperature up to 60 degrees Celsius. This heat isolation has many advantages. It mainly reduces vapor lock and aging of the seals. tests have also shown better brake efficiency in both very hot as very cold conditions. This product is actually distributed by EVO Corse ( www.evocorse.com )