R.I.C. srl

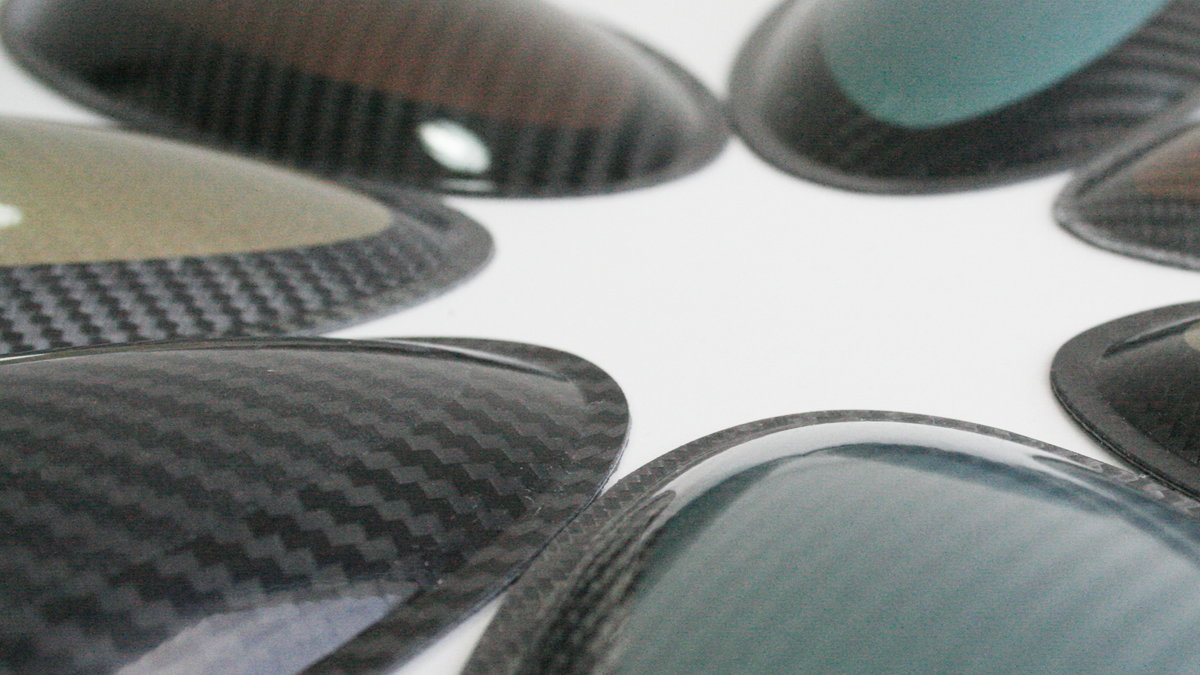

Carbon fiber products & Engineering

For more than 15 years R.I.C. works in the composite materials industry offering engineering, product development and production services for mainly carbon fiber parts. We are able to develop and produce products starting from zero up to a ready to sell turnkey end-product.

We start from feasibility studies and more detailed engineering studies done in close collaboration with our customer. We then proceed with the design and development of the molds and tools, make prototypes or preseries, test, validate and produce the product.

Our internal quality management system helps us to guarantee a constant product quality and no delays in delivery. We give much importance to quality. We have a ISO 9001 and ISO 13485 certification which allows us also to develop and produce medical components and tools up to class 2a. For some of these products we are also FDA registered.