Grazie a Competenze, Sinergia ed ottimizzazione dei flussi di lavoro e gestione qualità, riusciamo a sviluppare e produrre prodotti di qualità garantendo allo stesso tempo date di consegna e una qualità costante nel tempo del prodotto.

I servizi di R.I.C.

INGEGNERIZZAZIONE & RICERCHE3D digitizing, reverse engineering, CAD, CAM, FEA, problem solving, feasibility studies, detailed engineering studies, research and consulting.

INGEGNERIZZAZIONE & RICERCHE3D digitizing, reverse engineering, CAD, CAM, FEA, problem solving, feasibility studies, detailed engineering studies, research and consulting.

COMPRESSION MOULDINGCompression moulding is a technique which allows for a mass production of 3D components in composites combined with a constant quality. This techniques allows for the substitution of 3D forged aluminium parts lowering weight and increasing strength.

COMPRESSION MOULDINGCompression moulding is a technique which allows for a mass production of 3D components in composites combined with a constant quality. This techniques allows for the substitution of 3D forged aluminium parts lowering weight and increasing strength.

Services :

Product development, engineering, mould design, mould construction, prototyping, testing, validating, production, routing and surface finishing.

PRESS MOULDINGThis technique allows for the production of shell type composite products. Although less flexible than autoclave production, this technique consents to produce composite components in mass with a constant quality.

PRESS MOULDINGThis technique allows for the production of shell type composite products. Although less flexible than autoclave production, this technique consents to produce composite components in mass with a constant quality.

Services :

Product development, engineering, mould design, mould construction, prototyping, testing, validating, production, routing and surface finishing.

INIEZIONE A FIBRE LUNGHESince 10 years we produce high strength components with longfiber thermoplastic glass reinforced injection moulding materials. Over the last few years new materials based on carbon fiber and special polymers like PEEK, PEI, PC or nylon are available in the market allowing for the development of metal substitutes.

INIEZIONE A FIBRE LUNGHESince 10 years we produce high strength components with longfiber thermoplastic glass reinforced injection moulding materials. Over the last few years new materials based on carbon fiber and special polymers like PEEK, PEI, PC or nylon are available in the market allowing for the development of metal substitutes.

Services :

Product development, mould design, mould construction, production.

SOVRA-INNIEZIONESometimes there is a need to combine composites with polymers in order to satisfy design or mechanical requests. In these cases over-injection moulding is an option.

SOVRA-INNIEZIONESometimes there is a need to combine composites with polymers in order to satisfy design or mechanical requests. In these cases over-injection moulding is an option.

Services :

Product design, mould design, mould construction, production

IN-MOULD DECORATION / VERNICIATURAComposite material components often need a surface finish after beeing moulded and routed. This is normally done with the use of a coating process. Our pressmoulding technique allows for a surface layer to be co-moulded. This surface layer ensures no surface voids, a coating like top surface and the upportunity to colour this layer under the skin with multiple colours. This special layer also makes the component more tenace and can allow for overinjection. This techniques is normally identified as in-mould decoration.

IN-MOULD DECORATION / VERNICIATURAComposite material components often need a surface finish after beeing moulded and routed. This is normally done with the use of a coating process. Our pressmoulding technique allows for a surface layer to be co-moulded. This surface layer ensures no surface voids, a coating like top surface and the upportunity to colour this layer under the skin with multiple colours. This special layer also makes the component more tenace and can allow for overinjection. This techniques is normally identified as in-mould decoration.

Services :

Product design, mould design, mould construction, production.

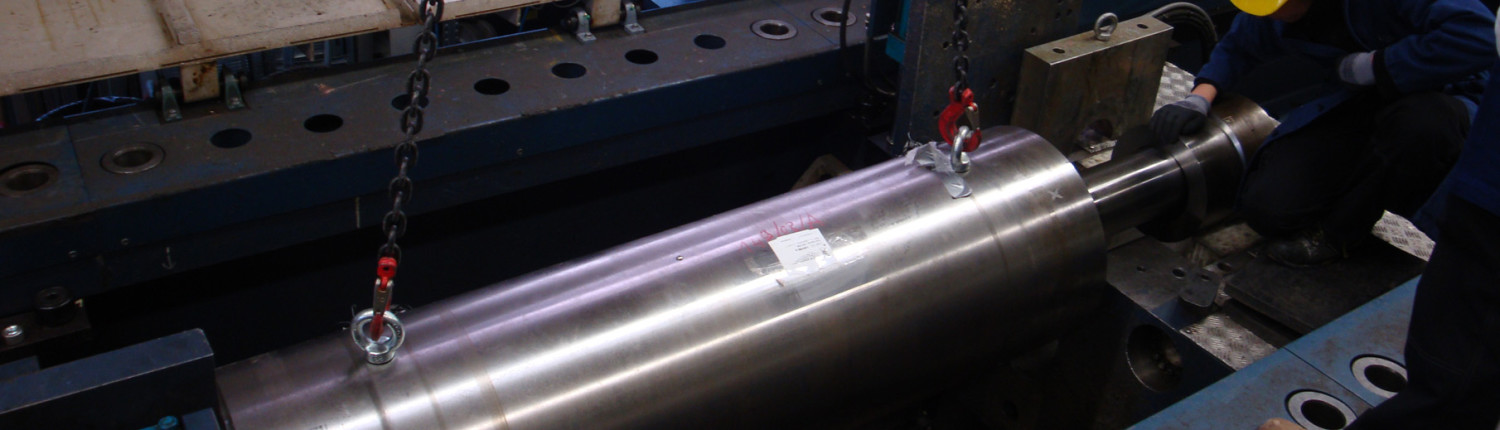

PRODOTTI SPECIALIA richiesta del cliente sviluppiamo prodotti speciali per una varietà di settori diversi. Usiamo tecniche come il M.I.M. (Metal Injection Molding), ceramiche tecniche, gorilla glass, nano metalli, alluminio anodizzato, INVAR, Materiali compositi, PEEK ed altri materiali e/o tecniche avanzate.

PRODOTTI SPECIALIA richiesta del cliente sviluppiamo prodotti speciali per una varietà di settori diversi. Usiamo tecniche come il M.I.M. (Metal Injection Molding), ceramiche tecniche, gorilla glass, nano metalli, alluminio anodizzato, INVAR, Materiali compositi, PEEK ed altri materiali e/o tecniche avanzate.

PRODOTTI MEDICISviluppiamo e produciamo componenti ed attrezzature per il settore medico e dentale. La nostra gamma di prodotti va da orthesi, perni dentali ad attrezzature speciali e per la chirurgia.

PRODOTTI MEDICISviluppiamo e produciamo componenti ed attrezzature per il settore medico e dentale. La nostra gamma di prodotti va da orthesi, perni dentali ad attrezzature speciali e per la chirurgia.

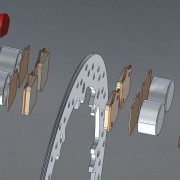

THERMOBRAKES“Thermobrakes” è il nome di un “Shim” termicamente isolante usato nei freni a disco per auto e moto. Questo “shim brevettato riesce ad abbassare la temperatura del olio sino a 60 gradi Celsius. Questo isolamento termico ha molti vantaggi. Principalmente riduce l’effetto “vapor lock” e l’invecchiamento delle guarnizioni. Inoltre test dimostrano un miglioramento dell’efficienza frenante sia in ambiente caldo che freddo. Questo prodotto viene attualmente distribuito dal EVO CORSE ( www.evocorse.com ).

THERMOBRAKES“Thermobrakes” è il nome di un “Shim” termicamente isolante usato nei freni a disco per auto e moto. Questo “shim brevettato riesce ad abbassare la temperatura del olio sino a 60 gradi Celsius. Questo isolamento termico ha molti vantaggi. Principalmente riduce l’effetto “vapor lock” e l’invecchiamento delle guarnizioni. Inoltre test dimostrano un miglioramento dell’efficienza frenante sia in ambiente caldo che freddo. Questo prodotto viene attualmente distribuito dal EVO CORSE ( www.evocorse.com ).